Dr. Petry / News

Latest News from Textilchemie Dr. Petry GmbH

Our success is based on researching innovative processes for the textile finishing industry. We continuously develop new products and textile auxiliaries for pretreatment, dyeing, textile finishing, softening, resin finishing, yarn lubrication, coating, printing and garment finishing.

On this website, you will find interesting news, current themes from our development department, information about innovative application technologies and details on our latest product advancements. Over our social media channels you can check out the current trends in textile chemistry. Sign up for our newsletter today and we always keep you up to date with the latest developments.

- All

- Company

- Exhibitions & Events

- Garment

- Products & Methods

- Yarn

Audit 2024 for Quality and Environmental Management Successfully Passed

Textilchemie Dr. Petry is a quality and environment-oriented chemical company specialized in the production of textile auxiliaries for the finishing industry. For the 31rd time in a row, we have successfully passed the annual DIN-EN-ISO audit for quality and environmental management. This year’s monitoring audit took place on 19 February 2024 at our subsidiary in Sennwald, Switzerland, as well as on 20 and 21 February 2024 at the headquarters in Reutlingen, Germany.

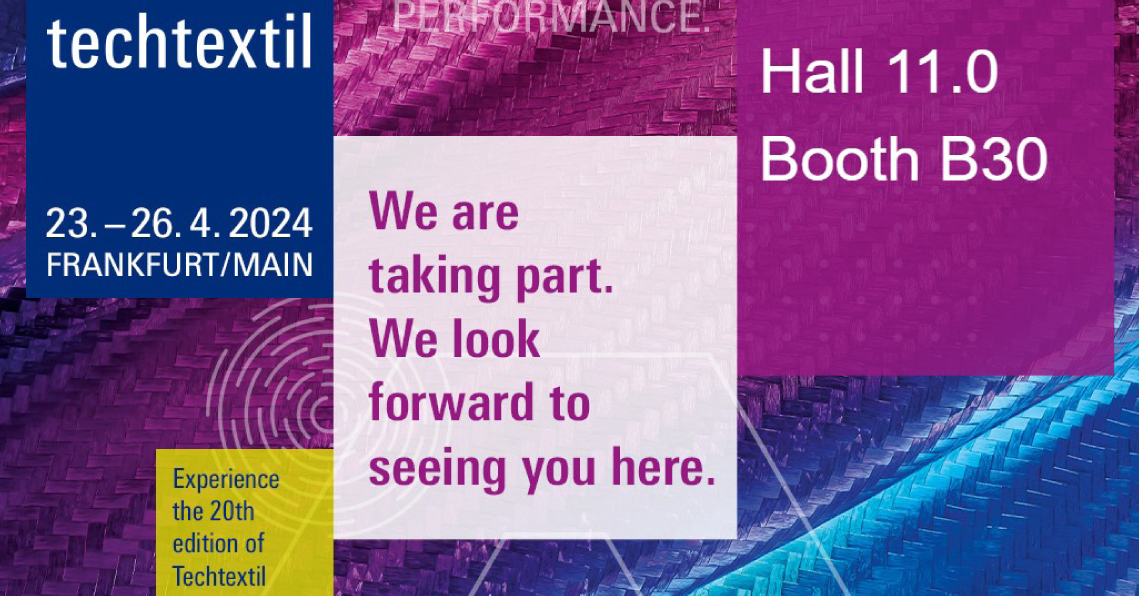

We meet you at Techtextil 2024!

Techtextil, the leading international trade fair for technical textiles and nonwovens, will take place in Frankfurt from 23 to 26 April 2024. As experts in the finishing of technical textiles, we will once again be presenting our latest developments and bestsellers and look forward to varied discussions with customers and interested parties.

Textile chemistry meets art: PERIGEN CD as dyeing auxiliary for artists

Ebba Grahn discovered the levelling and penetrating agent PERIGEN CD during her master studies at the world-renowned Royal College of Art located in London. The Swedish artist uses the auxiliary in her art studio to achieve fast and reliable dyeing results on acrylic glass.

World Water Day 2023: Be the Change!

Water is a precious and valuable resource. World Water Day is taking place annually on 22 March. The first World Water Day was in 1993, and nowadays it is being convened by UN-Water which belongs to the United Nations. This year’s World Water Day 2023 is about “Accelerating Change”. Our specialists at Textilchemie Dr. Petry will advise you if you would also like to make a contribution to saving water in your textile mill.

Textilchemie Dr. Petry takes over textile auxiliary division of Industrie-Chemie Stein

Textilchemie Dr. Petry GmbH from Reutlingen takes over service, consulting and distribution of the textile auxiliary division of Industrie-Chemie Stein GmbH (ICS) from Hechingen on January 1, 2023. Customers of ICS can rely on the consistent quality of the textile auxiliaries they are used to and first class service from the experienced application engineers at Dr. Petry.