Removal of Hydrolyzed Dyestuff after Reactive Dyeing

Reactive dyes are covalently bound to the cellulosic fibers during dyeing. Due to the strong bonds between dyes and fibers, reactive dyeings show particularly good fastness properties. However, during the dyeing process an unwanted side reaction, the so-called hydrolysis, can occur. The hydrolyzed dyes adhere only superficially to the fibers and need to be removed from the goods after dyeing. Otherwise, dyestuff hydrolysate which is not removed from the dyed fabrics can deteriorate the fastness of the dyed or printed goods. Furthermore, it may stain or soil other textiles when washed or rubbed. In order to achieve the required wet fastness levels, unfixed dyes have to be thoroughly removed in the rinsing and soaping process after dyeing.

For dyeing with reactive dyes, high amounts of salt and alkaline are used. However, salt has a negative impact on the washability of the dye hydolysate. Usually, the hydrolized dyestuff can only get washed out after the salt is removed as much as possible.

Use of PERLAVIN SRS/N for Soaping Reactive Dyeings

PERLAVIN SRS/N can be used for soaping in dyeing mills on both continuous as well as discontinuous ranges. PERLAVIN SRS/N is an excellent, highly efficient liquid soaping agent with good efficiency even in the presence of high salt contents. This saves several rinsing baths for salt removal after dyeing before soaping. Usually, one warm rinsing bath or a short rinsing in overflow is sufficient after dyeing.

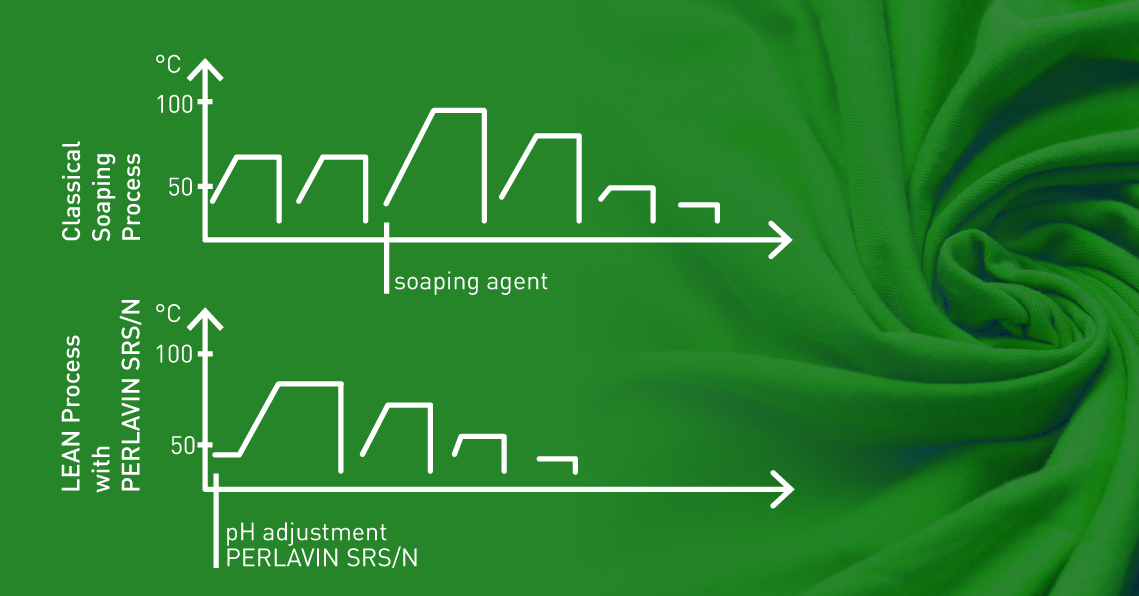

After rinsing, the pH value of the liquor is adjusted to pH 7 to 9. Normally, the soaping process is carried out at 98 °C. In contrast, when using PERLAVIN SRS/N soaping can be carried out at lower temperatures. Depending on the dyestuff and color depth, the fabric can be soaped at soaping temperatures between 60 °C and 98 °C. In most cases, even with very color-intensive reactive dyeings, a single soaping step is sufficient. Excellent wet fastness properties are also achieved on fiber blends of cotton with elastane by aftersoaping with PERLAVIN SRS/N.

Shortened Rinsing and Soaping Process

The complete rinsing and soaping process with bluesign®-approved PERLAVIN SRS/N is significantly shortened as rinsing steps before soaping can be skipped and due to the lower soaping temperatures. This helps saving water, energy and time.

Advantages of PERLAVIN SRS/N

Soaping with PERLAVIN SRS/N offers the following procedural advantages:

- excellent removal of reactive dye hydrolysate

- high efficiency even with high salt content

- good cleaning effects with high water hardness

- shortened rinsing and soaping process

- flexible soaping temperature higher than 60 °C

- significant savings in water and energy

Modern, Sustainable LEAN Processes Provide Benefits

Textilchemie Dr. Petry recommends modern, sustainable LEAN Processes for many applications in textile finishing which provide advantages in process engineering. Compared to classical methods our LEAN Processes offer ecological and economic benefits.

Our LEAN Processes are characterized by:

- Less time

- Economical processes

- Advanced chemistry

- New technologies

Our LEAN Processes for Wet Finishing of Cotton Textiles

PERLAVIN SRS/N is used for soaping and is part of our LEAN Textile Finishing. LEAN Processes applied in wet finishing of cotton textiles include:

- bioscouring with pectinase enzymes such as PERIZYM DBS for one-stage desizing and enzymatic scouring of starch-sized cotton fabrics

- grey dyeing of cotton with PERLAVIN NDA

- soaping with PERLAVIN SRS/N at lower temperatures

Subscribe to Our Newsletter

Are you interested in our news subjects? Please subscribe to our newsletter or follow our social media channels. On Xing, LinkedIn and Facebook, as well as through our newsletter, which is released every two months, you can receive interesting information about textile-chemical topics, current notifications about our company and news concerning our product range.